Hotline Numbers

020-82227376(Mr. Deng)

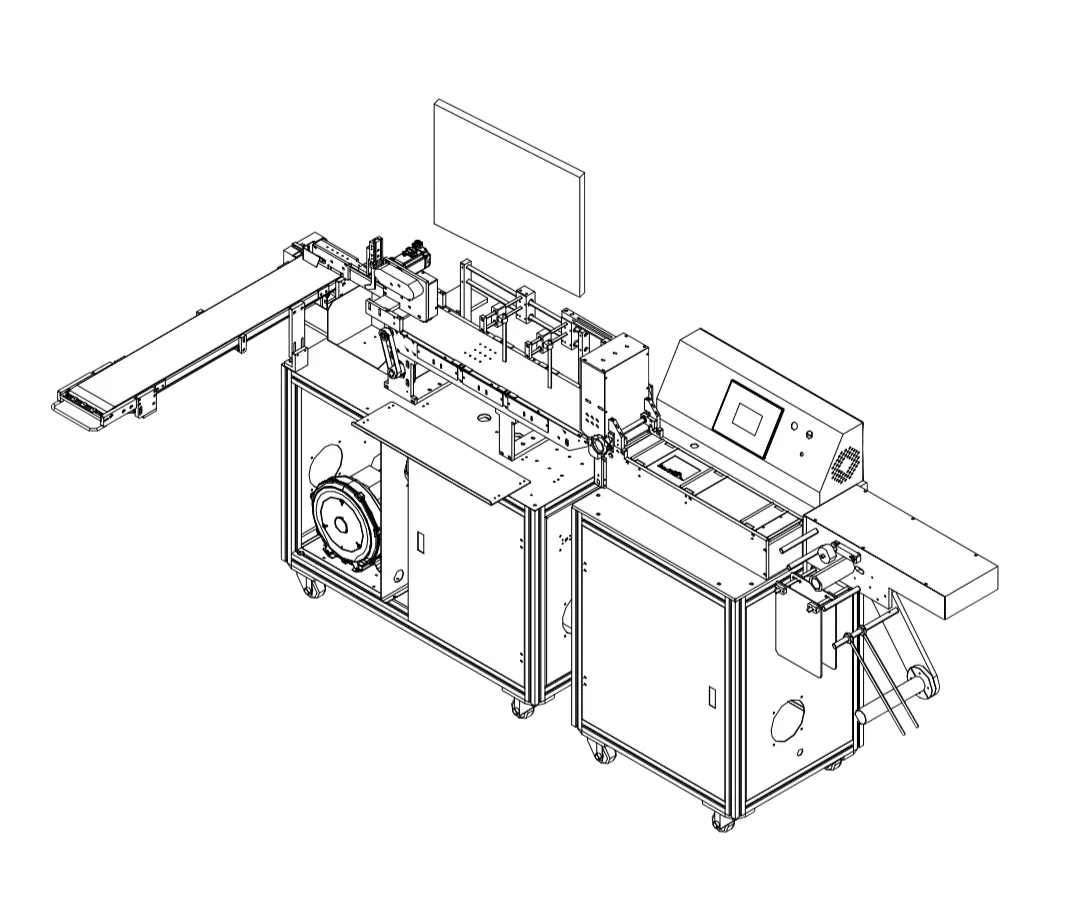

Cutting speed: | Max. 60M/min |

| Encoding speed: | Max. 360Pcs/min |

| Lable width: | 20-100mm; |

| Function: | Cutting of individual labels, high-speed inspection and coding |

| Machine Size: | 2534*1298*1526(mm) |

| Power: | 220V 50-60Hz 2KW(100C) + 3KW(421) |

| Weight: | 150Kg(100C) + 192Kg(421) |

The above parameters are for reference only. The exact details should be confirmed with the actual product.

RFID ultrasonic cutting and coding inspection equipment

-This equipment is suitable for the automatic material separation, inspection and coding of single labels such as single hanging tags, cards, tickets, and fabric labels.

-The vacuum feeding mechanism improves the feeding efficiency.

-The equipment is equipped with an automatic alarm function for heavy materials during material separation.

-Equipped with a dual-position RFID coding and reading detection configuration to ensure the accuracy of the data;

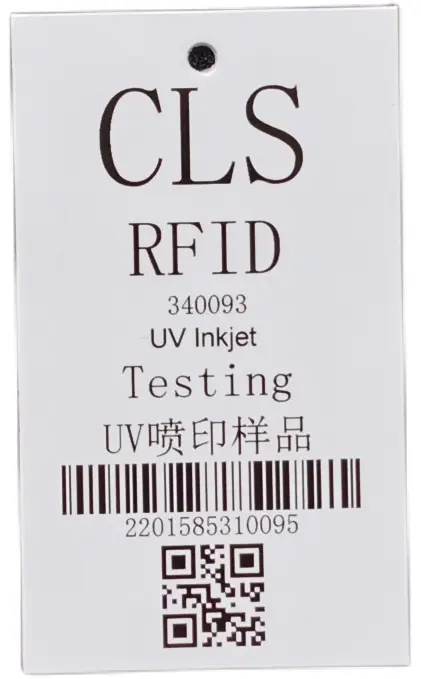

-Equipped with barcode scanner function, it enables consistent barcode printing and EPC data.

-Optional inkjet printing equipment can be equipped to apply labels or markings to the products.

-It has the functions of receiving materials, stacking, counting, and separating and stacking.

-The equipment is equipped with an automatic rejection and collection function for faulty labels and the corresponding mechanism.

-You can choose to install a barcode printer device, which enables the complete process of printing, scanning, coding, and verification in one go.

-An optional fabric label star wheel materializing mechanism can be selected, enabling the coding and detection functions for fabric labels.

Questions?

CLS technical consultants have the answer for you!

020-82227376

808@clsgd.com