产品分类/Categories

当前位置::首页 >

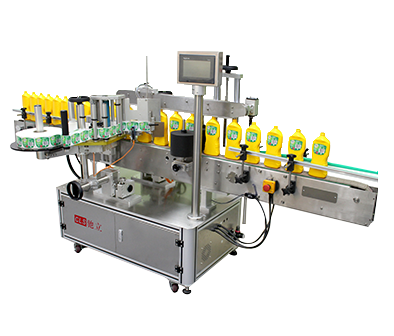

DOUBLE-SIDE LABELLING MACHINE MODEL: CL-2282

|

Features | |

|

1. Advanced touch screen HMI control system to achieve easy convenient operation. 2. Adopt German SIEMENS PLC to make closed-loop of control for servomotor, to achieve full automatic high speed labeling 3. 750W high-power, high-precision ultra small inertia servomotor. Labeling speed reach 4. Automatic rectified system for label acting on label feeding mechanism to achieve higher labeling precision 5. Self-adaption for constant fore of label feeding press roller, when replace different width of label is not require to adjust roller pressure to guarantee deviate 6. High speed、high torque label feeding servo system to make the accuracy of label sending under controlling within ± 7. Constant force winding device to avoid body paper winding in label roller or body paper winding too tight to clear such situation. 8. Special material of label feeding drive roller to make more stability process of label feeding will not make label damaged as well (especially for transparent label ) 9. Conveyer system is adopted ultra power of AC-motor to stably bottle feeding speed. Conducive to labeling accuracy. 10. It can be 7 dimensional space adjustable of labeling heads, and optionally adjust the labeling angle, conveniently to label all kinds of high difficult transparent label 11. Reserve online interface function, conveniently for connecting with other equipments 12. Wheel rotary type designed, conveniently to move to different occasion, fast adjustment, high efficiency of production. 13. Optional equipping additional double label pedestal plate mechanism, easy to change label enhancing efficacy 14. Optional equipping additional round bottle labeling mechanism, increase the flexibility and labeling variety for the machine 15. Optional equipping inkjet code entrainment at the bottom of machine 16. The machine mechanical structure is using strengthen rigidity design, simple, calm and steady. | |

|

Technical Parameters | |

|

The method of speed adjustment: |

uninterrupted - adjust rate |

|

Speed of label output (Max.): |

60 meters/min. |

|

Labeling speed (Max.): |

200 pcs/min (Subject to actual product size) |

|

Label feeding accuracy: |

± |

|

Labeling accuracy: |

± |

|

Max speed of conveyor: |

|

|

Label width (Max.): |

|

|

Label roll internal diameter: |

Φ |

|

Label roll external diameter: |

Φ |

|

Bottle size: thickness(width): |

≤ |

|

Apply range: |

double-side products labeling |

|

Height of conveyor: |

|

|

Machine dimension: |

3000×1600× |

|

Power supply: |

Three-phase 380V 50 Hz 3000W |

|

Air consumption: |

|

|

Weight: |

About |

|

| |

公司邮箱:cls@clsgd.com